Views: 0 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

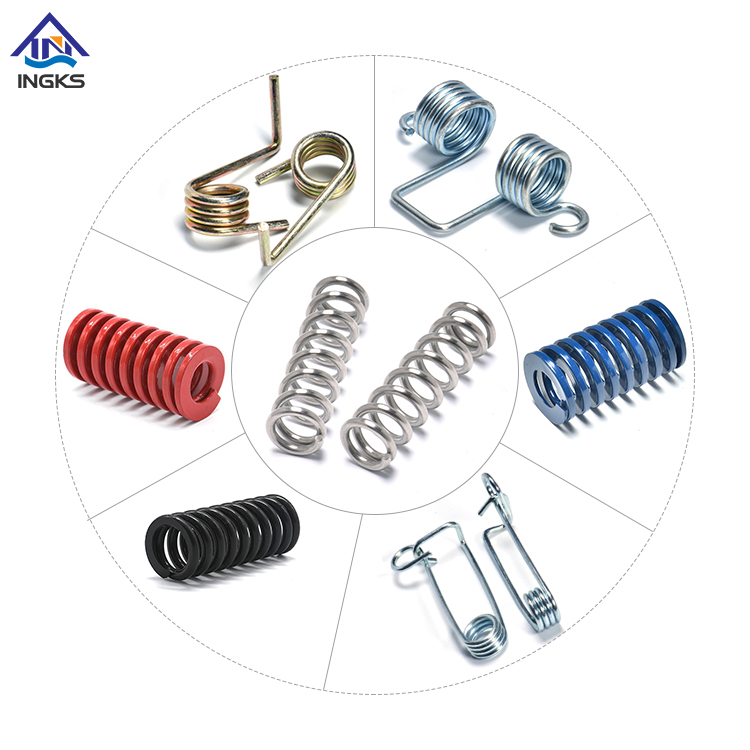

Ever wondered how coil springs support cars and machinery? These essential components absorb shocks and maintain stability. Coil springs are vital in modern engineering, enhancing safety and performance. In this post, you'll learn about coil spring manufacturing, including materials, design, and innovative techniques.

Coil springs are made from various materials, each chosen for its unique properties. The most common materials include:

● Music Wire: Known for its high tensile strength, it suits applications requiring strong, durable springs.

● Stainless Steel: Offers excellent resistance to rust and corrosion, ideal for moist or corrosive environments.

● Chrome Silicon: Provides high strength and can withstand elevated temperatures, making it perfect for demanding conditions.

● Oil Tempered Wire: Commonly used in general applications but less strong than chrome silicon or music wire.

● Chrome Vanadium: Similar to chrome silicon, it performs well under high temperatures and heavy loads.

Besides these, specialty materials like Inconel, Elgiloy, titanium alloys, and non-ferrous metals such as phosphor bronze or beryllium copper are used for specific applications requiring unique characteristics.

Each material brings specific benefits:

● Music Wire: High fatigue resistance and tensile strength make it suitable for automotive and industrial springs.

● Stainless Steel: Corrosion resistance ensures longevity in marine or medical equipment.

● Chrome Silicon: Handles shock loads and high temperatures, often used in aerospace or heavy machinery.

● Oil Tempered Wire: Offers cost-effective performance for less demanding uses.

● Chrome Vanadium: Combines toughness and heat resistance, ideal for heavy-duty suspension springs.

Specialty alloys like Inconel resist extreme heat and corrosion, supporting applications in aerospace and energy sectors.

Selecting the right material depends on:

● Load Requirements: Higher loads need stronger materials like chrome silicon or chrome vanadium.

● Environmental Conditions: Corrosive or moist environments call for stainless steel or coated materials.

● Temperature Exposure: High temperatures require heat-resistant alloys.

● Fatigue Life: Applications with repeated loading benefit from materials with excellent fatigue resistance.

● Cost Considerations: Balancing performance with budget constraints is crucial.

Understanding these factors helps engineers and manufacturers ensure the spring performs reliably over its service life.

Tip: Always match spring material to the specific operating environment and load conditions to maximize durability and performance.

Designing a coil spring starts by calculating its key specifications. These include wire diameter, coil diameter, number of coils, and free length. Engineers use formulas to determine the spring constant (k), which measures how stiff the spring will be. The spring constant depends on the material’s modulus of rigidity and the spring’s geometry. Calculations also involve load capacity—the maximum force the spring can handle without permanent deformation or failure.

For example, the spring rate formula for a compression spring is:

k=8D3NGd4

where:

● G is the modulus of rigidity of the material

● d is the wire diameter

● D is the mean coil diameter

● N is the number of active coils

These calculations ensure the spring performs reliably under expected stresses and cycles.

Modern coil spring design relies heavily on software tools. These programs simulate how a spring behaves under different loads and conditions. Engineers can adjust parameters and instantly see effects on stress distribution, deflection, and fatigue life. Software like SolidWorks, AutoCAD, or specialized spring design tools help optimize coil springs for performance and durability.

3D modeling allows visualization of the spring in its assembly environment. Finite element analysis (FEA) predicts where stresses concentrate, helping avoid weak points. This reduces prototyping time and improves accuracy before manufacturing.

Space limitations often challenge coil spring design. The spring must fit within a specific area while delivering the required load capacity. Designers balance coil diameter, wire size, and number of coils to meet these constraints.

For instance, in automotive suspension, springs must fit compactly but absorb shocks effectively. Engineers consider the available space and required travel distance, ensuring the spring compresses without binding or buckling.

Load capacity is critical; the spring must handle maximum expected forces without permanent deformation. Overloading leads to fatigue failure or loss of elasticity. Therefore, engineers carefully calculate maximum and minimum loads, incorporating safety factors.

The winding process shapes metal wire into coil springs. Two main methods exist: cold winding and hot winding. Cold winding happens at room temperature and suits wire diameters up to about 26mm. It offers excellent precision and is common in many industrial applications. Because the wire stays cool, it keeps its strength and elasticity during forming.

Hot winding involves heating the wire to temperatures near 900°C before coiling. This method is necessary for thicker or tougher wires that are difficult to bend cold. Hot winding makes the metal more pliable, allowing it to form large-diameter springs or heavy-duty coils. Industries like mining, rail, and gas often require hot-wound springs due to their size and load demands.

Choosing between cold and hot winding depends on wire size, material type, and the spring's final use. Hot winding requires additional heat treatment steps to relieve internal stresses caused by heating.

Precision is crucial in coil formation. Each coil must have consistent diameter, pitch, and spacing to ensure the spring performs as designed. Even small variations can affect load capacity, fatigue life, and overall reliability.

Operators monitor parameters like wire tension, feed rate, and coil angle during winding. Tight control helps avoid defects such as uneven coils or wire deformation. Precision also impacts the spring’s ability to fit into assemblies and maintain consistent spring rates.

Manufacturers often use advanced measuring tools and sensors to verify coil dimensions in real time. This reduces waste and improves quality.

CNC (Computer Numerical Control) spring coiling machines revolutionize the winding process. They automate wire feeding, bending, and cutting with high accuracy. CNC controls allow quick changes in wire diameter, coil size, and pitch without manual adjustments.

These machines can produce complex spring shapes and patterns that manual coiling cannot achieve. They also maintain tight tolerances, ensuring each spring matches design specifications exactly.

CNC coilers improve efficiency, reduce human error, and enable high-volume production runs. They also support custom spring manufacturing by allowing rapid prototyping and design iteration.

Tip: Using CNC spring coiling machines enhances precision and flexibility, enabling manufacturers to meet complex design requirements and reduce production time.

Heat treatment plays a critical role in coil spring manufacturing by altering the metal’s internal structure to improve strength and durability. Common methods include:

● Annealing: This process softens the metal, reducing internal stresses and making it easier to work with during forming or further processing.

● Quenching: The spring is rapidly cooled from a high temperature, increasing hardness and tensile strength.

● Tempering: After quenching, tempering reduces brittleness while maintaining strength, balancing toughness and elasticity.

These treatments ensure the spring can handle repeated stress without permanent deformation or failure.

Heat treatment enhances key mechanical properties essential for coil springs:

● Tensile Strength: The ability to withstand pulling forces increases, allowing springs to bear higher loads.

● Fatigue Resistance: Springs endure millions of load cycles; heat treatment improves resistance to fatigue cracks and failure.

● Elasticity: Proper tempering maintains the spring’s ability to return to its original shape after compression or extension.

● Durability: Overall lifespan extends as the spring resists wear, deformation, and environmental effects better.

The right heat treatment process depends on the spring’s material, intended use, and performance requirements.

Beyond traditional heat treatments, advanced methods such as cryogenic treatment are gaining traction. This technique involves cooling springs to extremely low temperatures (around -196°C or -320°F) using liquid nitrogen. Benefits include:

● Enhanced Wear Resistance: Cryogenic treatment refines the metal’s microstructure, reducing surface wear.

● Improved Fatigue Life: It stabilizes retained austenite, a softer phase in steel, transforming it into martensite, which is harder and stronger.

● Dimensional Stability: Springs maintain their shape better over time, reducing the risk of sagging or distortion.

Though more costly, cryogenic treatment suits high-performance springs used in aerospace, motorsports, and heavy industrial applications.

Surface treatments play a vital role in coil spring manufacturing. They protect springs from corrosion, wear, and environmental damage. Without proper surface finishing, springs can rust or degrade quickly, reducing their lifespan and reliability. Treatments also improve the spring’s appearance, which matters for visible components in automotive or consumer products.

Surface treatments create a barrier between the metal and harsh conditions like moisture, chemicals, or extreme temperatures. This barrier helps maintain the spring’s mechanical properties over time. Additionally, surface finishing can reduce friction between coils in compression springs, lowering noise and wear during operation.

Several surface treatment methods exist, each offering unique benefits:

● Powder Coating: A dry powder is applied electrostatically and cured under heat. It provides a durable, colorful finish that resists chipping and corrosion.

● Electroplating: Metals like zinc, nickel, or chrome are deposited on the spring surface via an electric current. This enhances corrosion resistance and can improve aesthetics.

● Phosphating: A chemical conversion coating that improves paint adhesion and corrosion resistance. It also reduces friction between metal parts.

● Galvanizing: Zinc coating applied by hot-dip or electroplating methods. It offers excellent rust protection, especially in outdoor or moist environments.

● Epoxy Coating: A thick, protective layer that resists chemicals, abrasion, and corrosion. Often used in harsh industrial settings.

● Black Oxide: A chemical treatment that provides mild corrosion resistance and a sleek black finish, commonly used for aesthetic purposes.

Choosing the right coating depends on the spring’s application, environment, and required durability.

Corrosion resistance is key for spring longevity, especially in automotive, marine, or outdoor applications. Coatings like zinc plating or powder coating prevent rust formation that weakens the spring metal. In environments exposed to saltwater or chemicals, specialized coatings such as epoxy or nickel plating offer superior protection.

Aesthetics matter when springs are visible parts of a product. Bright chrome plating or black oxide finishes improve visual appeal while protecting the spring. Some coatings also reduce glare or provide a non-reflective surface, useful in certain industrial or military applications.

Surface finishing can also improve spring performance by reducing friction or preventing dirt buildup. For example, phosphating creates a textured surface that holds lubricants better, enhancing smooth operation.

Quality assurance in coil spring manufacturing ensures springs meet performance and safety standards. Several standard tests verify their strength, durability, and accuracy.

● Load Testing: Measures the force a spring can withstand at various compression or extension levels. It confirms the spring meets the required load capacity without permanent deformation.

● Fatigue Testing: Simulates repeated loading cycles to assess how long the spring lasts before failure. This test is crucial for applications where springs undergo constant use.

● Dimensional Inspection: Checks coil diameter, wire thickness, pitch, and free length to ensure the spring matches design specifications.

● Hardness Testing: Measures the surface hardness to confirm proper heat treatment and material strength.

● Surface Integrity Tests: Includes inspections for cracks, corrosion, or surface defects that could affect performance.

● Shot Peening Verification: Assesses the effectiveness of shot peening, a process that improves fatigue life by inducing compressive stresses on the spring surface.

Manufacturers must comply with industry standards to guarantee spring reliability and safety. Common standards include:

● ASTM (American Society for Testing and Materials): Provides specifications for materials, mechanical properties, and testing methods.

● ISO (International Organization for Standardization): Offers guidelines for quality management and spring testing.

● SAE (Society of Automotive Engineers): Defines standards specific to automotive springs.

● DIN (Deutsches Institut für Normung): German standards that cover spring dimensions and mechanical properties.

Compliance involves thorough documentation, traceability, and adherence to testing protocols. This ensures springs perform consistently across batches and meet customer requirements.

Quality teams oversee every stage of coil spring production. Their responsibilities include:

● Reviewing Design and Specifications: Ensuring drawings and material selections meet performance needs.

● Monitoring Production Processes: Verifying that coiling, heat treatment, and surface finishing follow prescribed parameters.

● Conducting Inspections and Tests: Performing dimensional checks, mechanical tests, and surface examinations.

● Implementing Corrective Actions: Addressing any deviations or defects promptly to maintain quality.

● Maintaining Documentation: Keeping detailed records for audits, certifications, and customer assurance.

These teams collaborate closely with engineers and operators to uphold strict quality standards. Their vigilance reduces defects, prevents failures, and builds customer trust.

Heavy coil springs play a crucial role across many industries. Their ability to absorb shock, support loads, and maintain mechanical force makes them indispensable in demanding environments. Key industries include:

● Automotive: Coil springs are vital in vehicle suspensions, clutch mechanisms, and shock absorbers. They help smooth rides, improve handling, and ensure safety.

● Construction: Heavy machinery and equipment use coil springs for vibration control and load support. They contribute to the durability and efficiency of cranes, bulldozers, and excavators.

● Energy: Power plants and renewable energy systems rely on coil springs to manage mechanical movement and absorb stress. They are found in turbines, generators, and drilling equipment.

● Mining and Quarry: Springs help absorb shocks and vibrations in heavy equipment, improving reliability under harsh conditions.

● Rail and Transportation: Coil springs support railcar suspensions, helping maintain stability and comfort during transit.

In the automotive sector, coil springs are essential for suspension systems. They absorb road shocks, maintain tire contact, and enhance vehicle stability. Heavy-duty coil springs in trucks and SUVs handle greater loads and rough terrain, ensuring durability and driver comfort.

Construction equipment uses coil springs to dampen vibrations and shocks. This protects both the machinery and operators, extending equipment life. For example, springs in hydraulic systems and loaders help absorb sudden impacts and reduce wear.

The energy sector demands springs that withstand extreme conditions and heavy loads. Coil springs in turbines and generators manage mechanical stress during operation. They ensure smooth motion and reduce wear on critical components.

In renewable energy, such as wind turbines, coil springs help absorb vibrations caused by wind fluctuations. This increases system reliability and reduces maintenance needs.

Furthermore, coil springs are used in oil and gas drilling equipment. They absorb shocks from drilling operations, protecting tools and machinery in tough environments.

Material science is reshaping coil spring manufacturing. New alloys and composites offer improved strength, fatigue resistance, and temperature tolerance. For example, advanced titanium alloys provide excellent strength-to-weight ratios, ideal for aerospace and motorsports. Superalloys like Inconel withstand extreme heat and corrosion, extending spring life in harsh environments.

Nanotechnology and metallurgical breakthroughs refine microstructures, enhancing durability and elasticity. These innovations allow springs to perform reliably under heavier loads and more demanding conditions than ever before. Material improvements also enable lighter springs without sacrificing strength, benefiting industries focused on efficiency and sustainability.

Automation and robotics have revolutionized coil spring production lines. Robotic arms handle wire feeding, coiling, heat treatment loading, and packaging with high precision and speed. This reduces human error and improves repeatability, ensuring consistent spring quality.

Computer-controlled CNC coiling machines integrate seamlessly with robotic systems, allowing rapid changes in spring design parameters. Automated inspection systems use cameras and sensors to detect defects early, minimizing waste.

Robotics also enhance worker safety by reducing manual handling of heavy wire and hot components. The result is faster production cycles, lower costs, and higher throughput, meeting growing demand without compromising quality.

Looking ahead, digital transformation will further optimize spring manufacturing. Industry 4.0 technologies like IoT sensors and AI-driven analytics will monitor equipment health, predict maintenance needs, and optimize processes in real time.

Additive manufacturing (3D printing) may enable custom spring geometries unachievable by traditional methods, opening new design possibilities. Advanced simulation tools will improve virtual prototyping accuracy, reducing time to market.

Sustainability will drive innovations, focusing on eco-friendly materials, energy-efficient processes, and recycling programs. Manufacturers will increasingly adopt Life Cycle Analysis to minimize environmental impact.

Together, these trends promise smarter, faster, and greener coil spring production, supporting evolving engineering challenges.

Coil springs are crafted using advanced materials and precise engineering, ensuring durability and performance across industries. Leading manufacturers like Wuxi Ingks Metal Parts Co.,Ltd. offer innovative solutions, enhancing coil spring applications in automotive, construction, and energy sectors. Their commitment to quality and technological advancements ensures springs meet exacting standards, providing reliable service in demanding environments. With a focus on customer satisfaction, these manufacturers deliver exceptional products that add significant value to various engineering applications.

A: Coil springs are typically made from music wire, stainless steel, chrome silicon, oil tempered wire, and chrome vanadium, each chosen for their specific properties like tensile strength and corrosion resistance.

A: Coil springs in the automotive industry are crucial for suspension systems, absorbing road shocks, maintaining tire contact, and enhancing vehicle stability and safety.

A: Heat treatment improves coil springs' mechanical properties like tensile strength and fatigue resistance, ensuring they can handle repeated stress without deformation or failure.

A: CNC machines enhance precision and flexibility in coil spring production, allowing quick adjustments and complex designs while reducing human error and production time.

A: Surface treatments protect coil springs from corrosion and wear, improving their longevity and reliability, especially in harsh environments like automotive and marine applications.

A: Quality assurance ensures coil springs meet performance and safety standards through rigorous testing for load capacity, fatigue resistance, dimensional accuracy, and surface integrity.

content is empty!